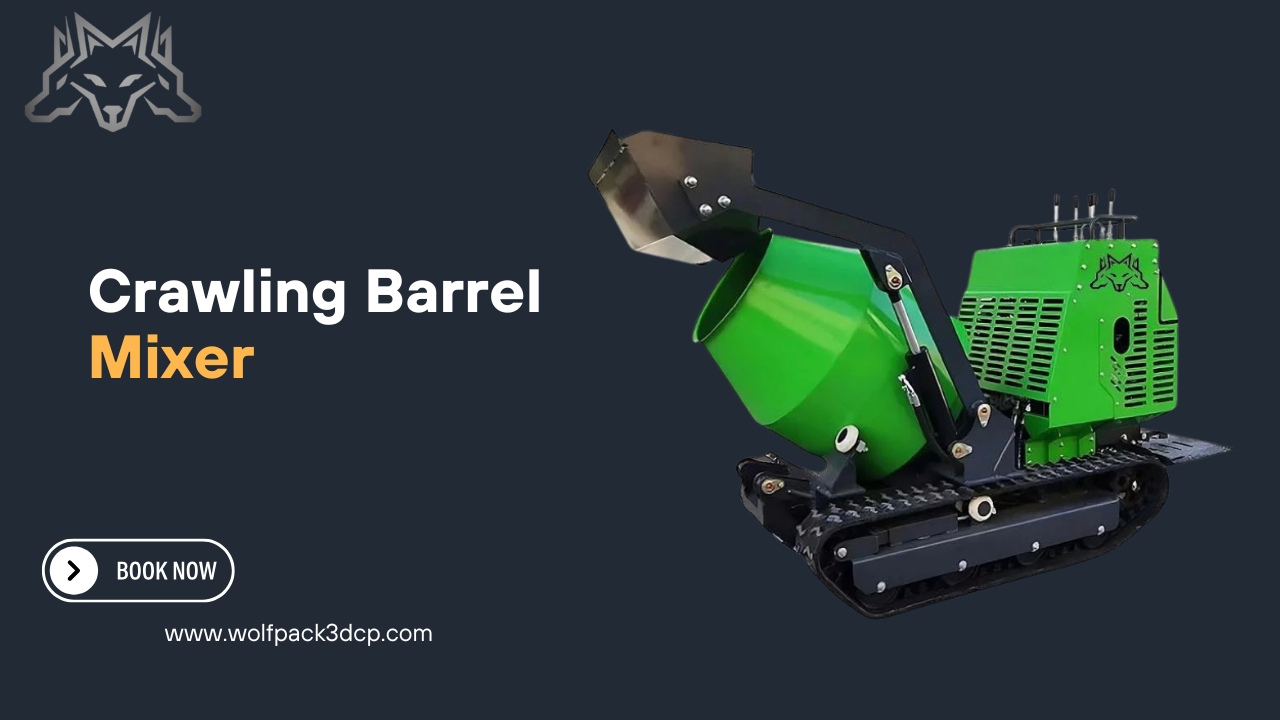

In the world of construction, efficiency, precision, and innovation are no longer luxuries — they are necessities. As the global construction industry moves toward automation and sustainable development, WolfPack 3DCP is leading the revolution with its Crawling Barrel Mixer, a next-generation 3D concrete mixing solution designed for maximum performance, mobility, and versatility.

1. What is a Crawling Barrel Mixer?

The Crawling Barrel Mixer by WolfPack 3DCP is a state-of-the-art machine designed to streamline the concrete mixing process in 3D printing construction. Unlike traditional mixers that require manual handling and complex setup, the Crawling Barrel Mixer features a self-moving, barrel-style system that ensures smooth, continuous, and uniform mixing of concrete materials.

This innovation eliminates downtime, reduces labor requirements, and allows for more accurate material consistency — essential for high-quality 3D-printed structures.

2. Key Features that Set It Apart

WolfPack 3DCP has engineered the Crawling Barrel Mixer to handle the toughest mixing challenges. Some standout features include:

-

Automated Mixing Mechanism: Ensures even blending of aggregates, cement, and additives for perfect concrete quality every time.

-

Mobility & Efficiency: The “crawling” functionality allows the machine to move across job sites independently, saving transport time.

-

Energy Efficiency: Built with optimized motor technology to reduce power consumption while maintaining strong performance.

-

Seamless Integration: Works perfectly with WolfPack’s other 3DCP products like the WP 3D Continuous Mixer and SCARA printing models.

-

Smart Controls: Equipped with intelligent control systems for easy operation, monitoring, and calibration.

3. Why Choose the Crawling Barrel Mixer for 3D Printing Construction

The construction industry faces challenges in achieving consistent concrete quality, especially in additive manufacturing. The Crawling Barrel Mixer addresses these challenges by ensuring precise material preparation — a critical step for successful 3D printing.

Key benefits include:

-

Enhanced mixing precision for layer-by-layer printing.

-

Reduced material waste and manual labor.

-

Increased operational speed and site productivity.

-

Compatibility with both small-scale and industrial 3D printing setups.

With its cutting-edge design, this mixer enables construction companies to achieve stronger, more sustainable, and more accurate structures faster than ever before.

4. WolfPack 3DCP – Buy or Rent for Maximum Flexibility

At WolfPack 3DCP, we understand that every project has different needs. That’s why, in addition to purchasing, we offer all our 3D printing machines — including the Crawling Barrel Mixer — for rent.

If your business needs high-quality equipment for a short-term project or for testing 3D construction before full investment, renting is a cost-effective solution.

When you rent from WolfPack 3DCP, you get:

-

Access to the latest technology without heavy capital investment.

-

Technical support and operational guidance.

-

Flexible rental plans that fit your project duration and scale.

Whether you’re a startup exploring 3D printing construction or a large firm handling multiple builds, our rental options empower you to move forward with confidence.

5. The Role of Mixing in 3D Concrete Printing

Mixing might seem like a small part of the construction process, but it’s one of the most critical stages in 3D concrete printing. The quality of your mix directly affects:

-

Print smoothness

-

Layer adhesion

-

Curing strength

-

Structure durability

The Crawling Barrel Mixer’s ability to maintain perfect material uniformity helps builders achieve better print outcomes, reduce defects, and extend the lifespan of their projects.

This precision mixing technology contributes not just to construction success, but also to sustainability by minimizing waste and energy consumption.

6. Future of 3D Construction with WolfPack 3DCP

WolfPack 3DCP is shaping the future of construction with automation, robotics, and digital manufacturing. The Crawling Barrel Mixer is part of a larger ecosystem of 3DCP equipment that works together to transform how we design and build.

With solutions like the SCARA Elite Roadrunner and WP 3D Continuous Mixer, WolfPack 3DCP enables builders to construct faster, smarter, and greener.

FAQs about the Crawling Barrel Mixer

Q1: Can I rent the Crawling Barrel Mixer instead of buying it?

✅ Yes! WolfPack 3DCP offers rental options for all machines, including the Crawling Barrel Mixer. Contact us for flexible rental plans.

Q2: What kind of projects can use this mixer?

It’s ideal for 3D concrete printing, modular construction, and on-site automated builds requiring precise material preparation.

Q3: Is the machine compatible with other 3D printing systems?

Absolutely. It integrates smoothly with all WolfPack 3DCP printing models and other compatible 3D construction systems.

Q4: How can I maintain the mixer?

The Crawling Barrel Mixer requires minimal maintenance. WolfPack 3DCP provides complete operational support and training.

Conclusion

The Crawling Barrel Mixer by WolfPack 3DCP isn’t just another mixing tool — it’s a step toward the future of automated, efficient, and sustainable construction. Whether you’re ready to buy or prefer to rent, WolfPack’s flexible solutions help you stay ahead in the fast-evolving world of 3D concrete printing.

👉 Visit wolfpack3dcp.com to explore more innovative 3DCP equipment or request rental details today.