Advanced plastic molding has been at the forefront of manufacturing innovation for decades. As industries continue to demand high-quality, cost-effective, and sustainable solutions, the techniques and technologies used in plastic molding are rapidly evolving. In 2025, businesses and manufacturers are expected to witness a series of transformative trends in advanced plastic molding that will redefine production processes and product capabilities. From automation to material innovations, these trends are shaping the future of manufacturing and offering competitive advantages to early adopters.

Understanding these trends is crucial for companies looking to stay ahead in the competitive landscape. By integrating the latest advancements, businesses can achieve faster production, higher precision, and reduced waste. Moreover, advanced plastic molding techniques are opening doors to new applications in industries such as automotive, medical, consumer electronics, and aerospace, where precision and material performance are paramount.

Automation and Smart Manufacturing in Advanced Plastic Molding

Automation is rapidly transforming the landscape of advanced plastic molding. Manufacturers are increasingly adopting robotic arms, automated injection molding machines, and computer-controlled systems to streamline production. These technologies reduce human error, enhance consistency, and accelerate production cycles, allowing companies to meet growing demand without compromising quality. Automation also enables predictive maintenance and real-time monitoring, helping manufacturers avoid downtime and maintain operational efficiency.

Moreover, smart manufacturing technologies, including sensors, IoT devices, and AI-driven analytics, are being integrated into advanced plastic molding processes. These tools allow manufacturers to track mold performance, detect anomalies, and optimize production parameters in real-time. The combination of automation and smart technologies ensures higher product quality and lowers operational costs, positioning companies to deliver superior products faster than ever before.

Sustainable and Eco-Friendly Materials

As environmental concerns continue to gain global attention, the use of sustainable materials in advanced plastic molding is becoming a major trend. Manufacturers are now focusing on biodegradable plastics, recycled polymers, and bio-based materials that reduce carbon footprints and align with regulatory requirements. These materials not only help companies comply with environmental standards but also attract eco-conscious consumers who prioritize sustainability in their purchasing decisions.

Additionally, advanced plastic molding techniques are adapting to process these innovative materials efficiently. New molding processes, such as low-energy injection molding and precision thermal management, enable the use of environmentally friendly polymers without compromising product quality. By integrating sustainable materials into their production pipelines, businesses can enhance brand reputation while contributing to a greener future.

3D Printing and Additive Manufacturing Integration

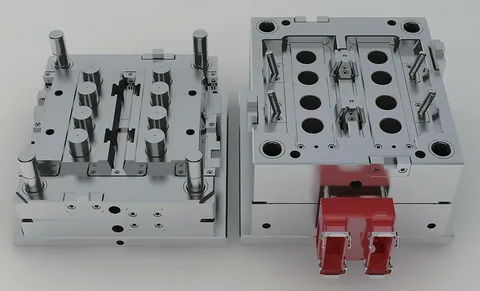

The integration of 3D printing and additive manufacturing with traditional advanced plastic molding techniques is reshaping the production landscape. Rapid prototyping using 3D printing allows manufacturers to test designs, optimize molds, and reduce development time before committing to full-scale production. This synergy between additive and traditional molding provides unparalleled flexibility in product design and innovation.

In 2025, hybrid manufacturing solutions are expected to become mainstream. Companies are using 3D-printed molds or mold inserts for small production runs, enabling quicker response times and reduced tooling costs. Advanced plastic molding combined with additive manufacturing also facilitates complex geometries and intricate designs that were previously impossible or cost-prohibitive, opening new opportunities in automotive, aerospace, and medical device industries.

Advanced Material Composites

The development of advanced material composites is another significant trend in advanced plastic molding. By combining polymers with fibers, fillers, or nanoparticles, manufacturers can create materials with superior strength, thermal stability, and chemical resistance. These composites are ideal for high-performance applications, such as lightweight automotive parts, durable consumer electronics, and medical devices requiring biocompatibility.

In addition, advanced plastic molding techniques are evolving to handle these composite materials efficiently. Multi-material injection molding and co-injection processes allow for precise layering and integration of different materials within a single product. This innovation not only improves product performance but also enables cost savings by reducing material usage and streamlining assembly processes. Companies leveraging these advanced composites are positioned to lead in high-demand sectors requiring specialized material properties.

AI and Predictive Analytics in Process Optimization

Artificial intelligence (AI) and predictive analytics are revolutionizing advanced plastic molding by providing data-driven insights into production processes. Machine learning algorithms can analyze historical data, detect patterns, and predict potential defects before they occur. This predictive approach minimizes waste, enhances mold longevity, and ensures consistent product quality, significantly improving manufacturing efficiency.

Furthermore, AI-driven simulation tools are enabling manufacturers to optimize mold designs, injection parameters, and cooling cycles. By simulating different scenarios before production, companies can identify the most efficient process configurations, reducing trial-and-error and saving time and resources. As AI continues to advance, its integration with advanced plastic molding will become essential for manufacturers seeking to maintain a competitive edge in an increasingly complex market.

Conclusion

The year 2025 promises exciting developments in advanced plastic molding, driven by automation, sustainable materials, additive manufacturing, advanced composites, and AI-powered analytics. Manufacturers who embrace these trends will not only achieve higher efficiency and product quality but also remain competitive in a rapidly evolving market. As technology continues to advance, the possibilities for innovation in advanced plastic molding are virtually limitless, offering opportunities to enhance performance, reduce costs, and promote sustainability.

Businesses that stay ahead of these trends can capitalize on the benefits of cutting-edge technologies while responding effectively to market demands. By investing in advanced plastic molding techniques and materials, manufacturers are setting the stage for a more efficient, innovative, and environmentally responsible future in production.